Why Wood Energy Recycler's Supports

Wood Residue Community-Scale Heating

Burning wood residue for heat:

- Keeps fossil fuel carbon in the ground,

- Makes use of wood carbon which is destined to return to the atmosphere quickly,

- Increases business/communities’ competitiveness by reducing heating costs,

- Keeps dollars in local communities and stimulates local economies.

- Creates local markets for the increasing supply of wood residue produced from climate change.

Good public policies are formed by weighing resulting costs and benefits. These benefits certainly need to be compared to both the existing situation and any environmental cost of burning this residue for heat.

Existing Situation

Wood residue’s carbon is wasted and its financial value is not recognized. Government leadership is needed to develop trustworthy scientific information on availability, current value, and emissions.

We all want zero-emission energy production, but so long as trees are cut we will have carbon emissions: When a tree grows it removes carbon from the atmosphere which is absorbed into the wood. The same amount of carbon will be released into the atmosphere if a tree is burned as when it decomposes. Remarkably little is actually known about the rate of carbon released during decomposition, but clearly the rate of decomposition increases when the wood is chipped, as it often is for transportation. Given that this carbon will return to the atmosphere in the short run doesn’t it make sense to use it to keep fossil carbon in the ground?

When wood decomposes in the absence of oxygen, methane gas is produced. Again, remarkably little is known about when and how much methane is produced under different scenarios. Given that we know this methane production is occurring, and methane’s significant impact on climate change, isn’t combustion which produces no methane a preferable option?

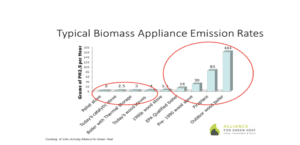

Wood stove emissions have only been regulated since 1990. Over the last 30 (plus) years there has been a significant decrease in particulate emissions from wood heating systems (see below). Despite these improvements, legacy inefficient wood combustion systems dominate public opinion. Burning wood has become a polarized environmental question that needs more impartial, scientific information. Are particulate emissions from oil-burning more abundant and more harmful than emissions from a modern wood heating system? These automatically fed systems should not be confused with legacy hand-fired systems.

Wood residue should be viewed as a financial drag on most local economies. Many wood residue markets do not cover the cost of transportation and processing. So, wood that is taken out of the forest, and becomes residue, currently carries negative or remarkably little value to the residue producer.

- For utilities, wood residue disposal increases the cost of electricity.

- For government agencies managing roadside trees, park trees, and forests, this residue disposal is an expense that must be paid by taxpayers. This expense will increase significantly as trees die from climate change.

- For private landowners and nonprofit organizations trying to manage forests, wood residue reduces the value of the harvest and makes this tree management more expensive.

- For industries that harvest wood, make carbon-sequestering wood products, or use wood for transportation or packaging, wood residue increases the cost of doing business and makes them less competitive.

When imported fossil fuel is burned for heat, most of the dollars spent for the heat flow down an energy pipeline, exiting the local community. As a result, these dollars are lost to the local economy. When wood is burned to displace imported fossil fuel, these dollars are more likely to stay in the local community. Dollars that stay in the local economy are spent over and over again creating a multiplier impact bolstering the local economy.

Large centralized wood power plants have dominated the conversation surrounding wood fuel’s “equity”. Certainly, sitting a centralized powerplant in an urban area that pollutes the air and brings far more costs than benefits to the local community is not fair to that local community. The equity balance changes when the local community is directly benefitting from the facility. The cost of the emissions has a benefit offset. Before judging wood fuel as an inequitable fuel source please closely consider modern wood heating’s emissions vs. the local benefits.

Many environmentalists correctly argue that when wood biodegrades important nutrients are returned to the soil so ideally wood should rot in place. Wood Energy Recyclers agrees with this perspective which is why our focus is on residue that “can not, or should not” be left in place.

A ton of green wood will produce the same amount of heat as $150 worth of heating oiler at $2/50/gallon. Dried wood produces even more valuable heat. The cost of turning wood residue into local wood fuel varies with location but can certainly be accomplished for considerably less than $150/ton. Large, inefficient wood electric generating stations are paying less than $30/ton in Massachusetts – less than it costs to get the wood to the facility.

Relatively little capital investment is required to set up community-scale wood processing plants to supply local heat demand. Wood processing equipment investment is already in place in most communities. The ubiquitous nature of wood residue offers a pathway for entrepreneurs to connect local thermal demand with locally available wood residue. It takes relatively little residue to heat a high school or other public building. We need to rethink how we handle wood residue.